This post contains affiliate links.

If you missed the first post in this series, it’s here: Making Friends With Your Sewing Machine: What Are All the Different Bits and What Do They Do?

Now you know what the different bits do, it’s time to set up your sewing machine so you can start sewing!

The first thing is to put the sewing machine on a table near a plug socket and plug it in. I’ve considered sewing with my machine on my lap, but I don’t think it would go well!

Plug the foot pedal into the sewing machine. On my sewing machine, the pedal plugs in next to the power cable. The pedal will need to be on the floor, next to your foot, with the fatter end of the wedge away from you.

Which Thread?

Before threading the sewing machine, it’s worth mentioning that what thread you use matters.

Cheaper thread is often not very smooth. It has places where it’s thinner and others where it’s thicker. The thinner bits mean that it’s more likely to break while you’re sewing, and the thicker bits make it more likely to snag the fabric or get stuck in the needle.

As this can potentially damage your sewing machine, it’s worth paying a bit more for decent thread. Gutermann and Mettler are both good.

The same goes for pre wound bobbins. It’s better in the long run to buy good thread and wind the bobbins yourself on your sewing machine.

How Your Sewing Machine Uses Thread

A sewing machine uses thread for top stitches, from the spool, and underneath stitches, from the bobbin.

So as well as the spool, you’ll need a bobbin wound with the same thread.

Winding the Bobbin

The first thing to do to set up your sewing machine is to wind the bobbin.

This is how I go about winding the bobbin on my sewing machine. Yours will probably be similar, but please check the manual!

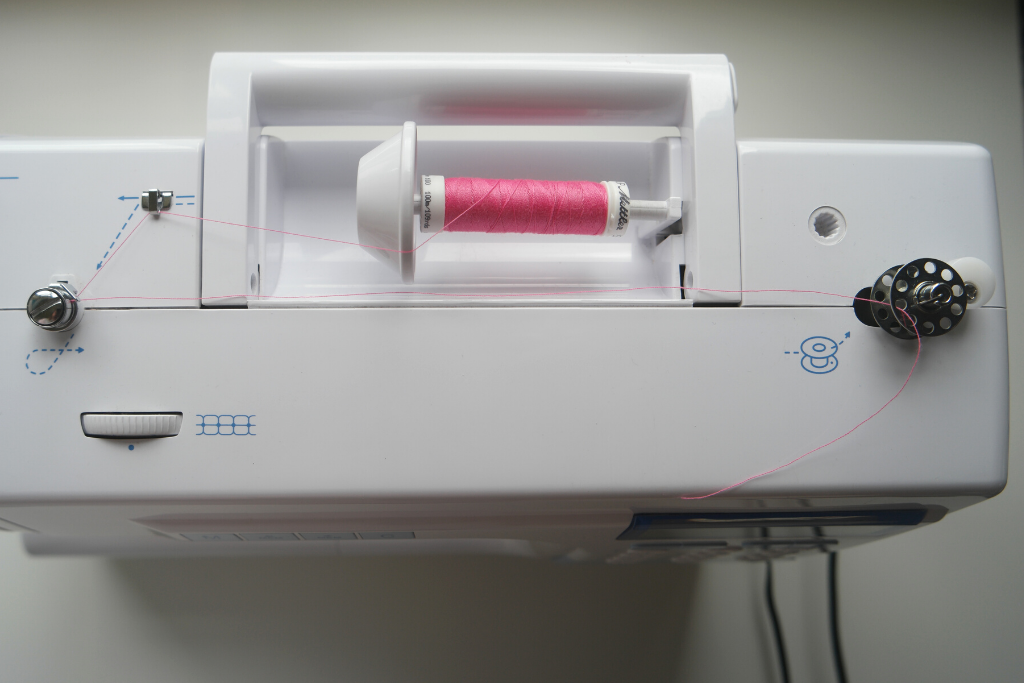

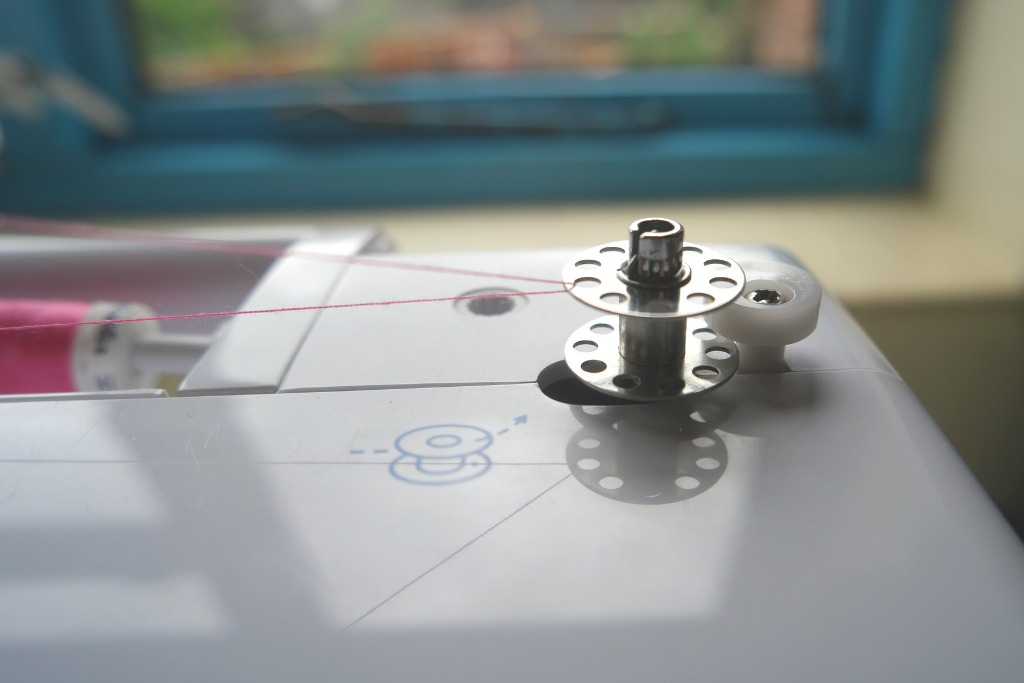

Slip the empty bobbin onto the bobbin pin.

Put the spool on the spool pin. The end of the thread should be on the top of the spool and when you pull the thread, the spool should turn towards you.

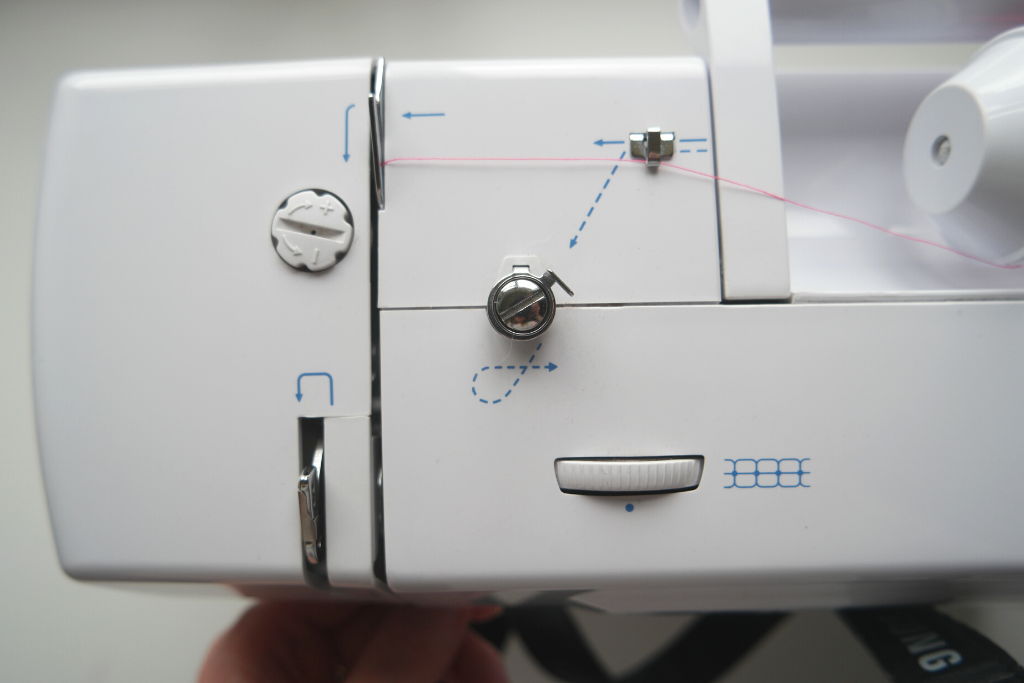

Take the thread through the thread guide, round the bobbin tension disc, then poke the end of the thread through one of the little holes in the top of the bobbin.

On my sewing machine, there are handy little arrows showing where the thread goes, so it’s very difficult to get this wrong.

Hold onto the end of the thread. With your other hand, switch the sewing machine on and push the bobbin pin across.

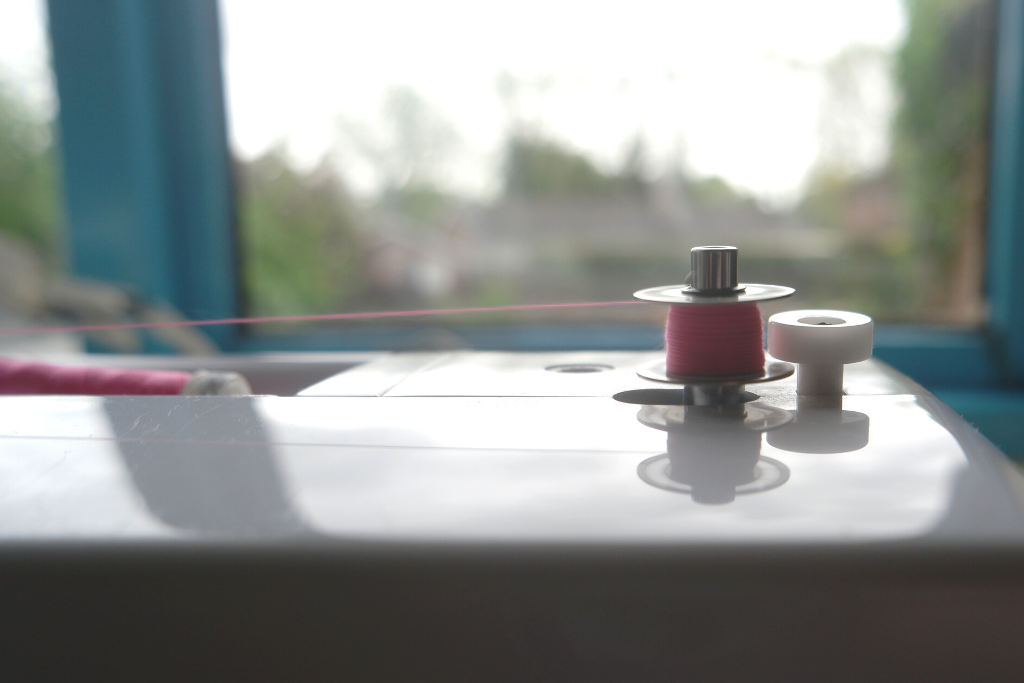

Gently press on the foot pedal and the bobbin with start to turn. When it’s been round a few times, you can let go of the thread. Cut it off. This is so that it doesn’t end up getting caught inside the sewing machine later.

Using the pedal, finish winding the bobbin.

On my sewing machine, it automatically stops when the bobbin is full. If yours doesn’t do this, stop winding when the thread is covering the little holes.

Cut the thread, slide he bobbin pin back over and take the bobbin off the bobbin pin.

Putting the Bobbin Into the Sewing Machine

On some sewing machines, the bobbin drops into a little bobbin sized space underneath the needle. On others, you have to put the needle into a little case and slot it into an opening on the front of the machine.

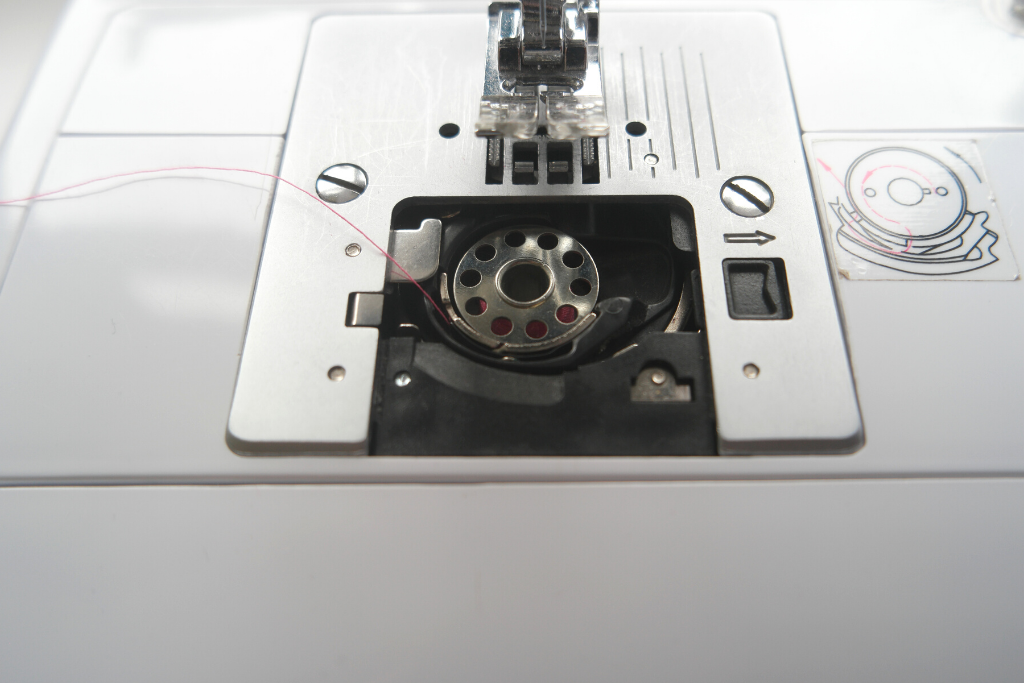

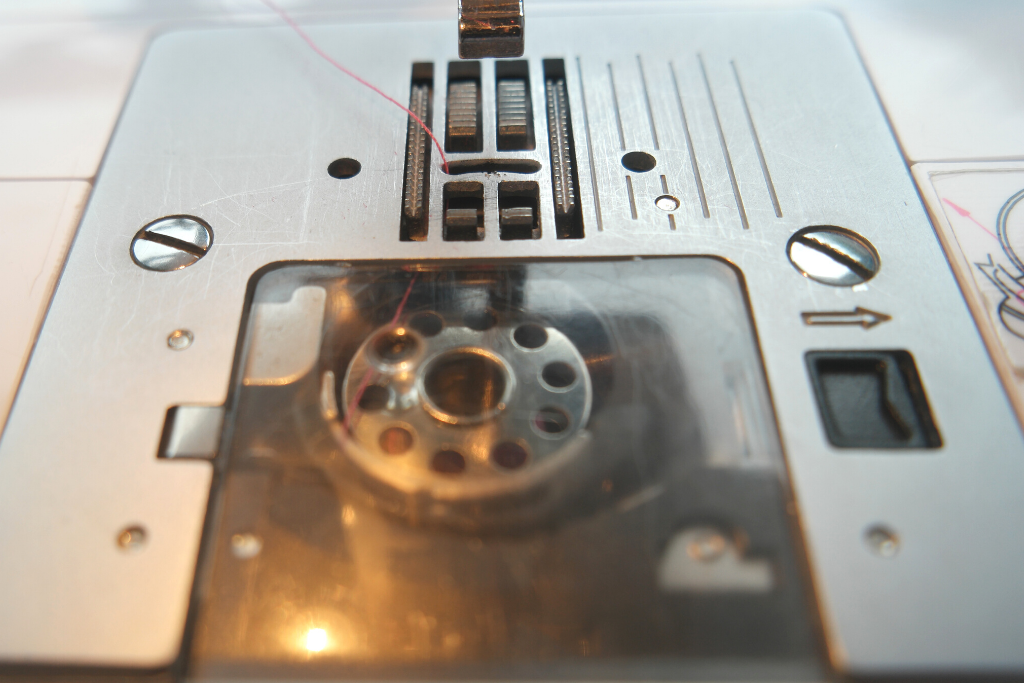

Drop In Bobbins

Remove the little plastic plate.

Take your bobbin and drop it into the bobbin hole. Check that the bobbin turns anti clockwise when you pull the thread.

Leave enough of a tail so that there is some thread protruding when you put the plastic plate back on.

Front Loading Bobbins

Pop the bobbin into the little case and pull the thread through the hole. When you pull the thread, the bobbin should turn in a clockwise direction.

Slot the bobbin with its case into the opening and close the little door.

Threading the Sewing Machine

Things might be slightly different on your sewing machine, so it’s a good idea to check the manual first. However, the basic principle will be the same for all sewing machines.

If you haven’t done so already, pop the spool on the spool pin. Check that the spool turns towards you when you pull the thread.

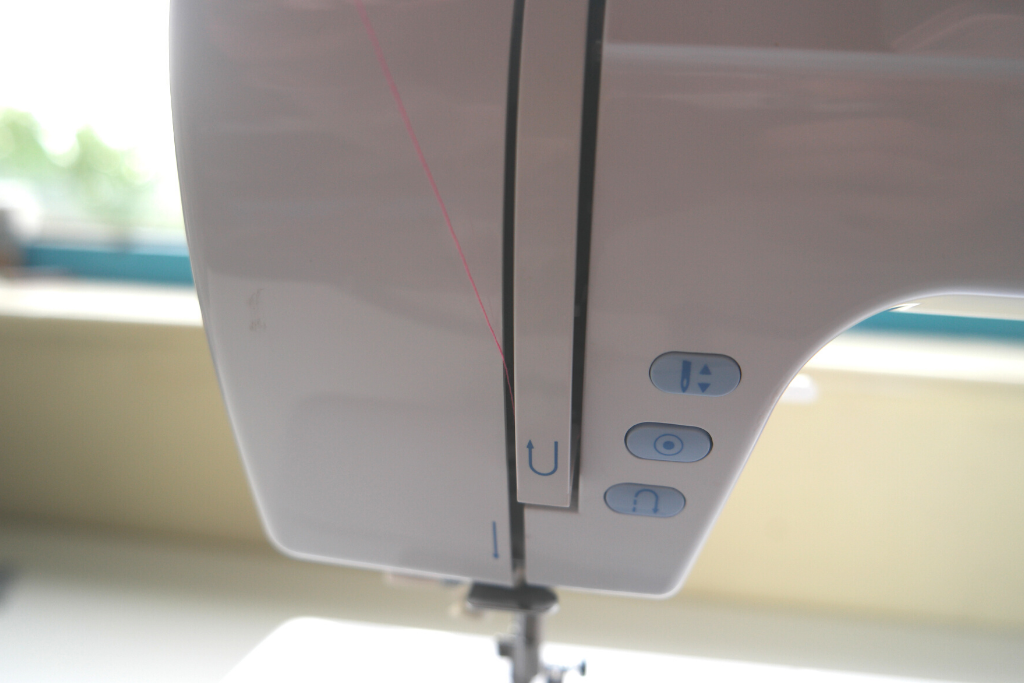

The first place the thread will need to go is through the tension discs. There might be a thread guide to make sure that the thread is in the right place. On newer machines, the bit where the tension discs are will probably look like they do on mine. On an older sewing machine, they might be part of a dial on the front.

The next place for the thread to go is through the take up lever.

After that the thread will need to go through the needle. Again, there will probably be a thread guide so that the thread is in the right place for the needle. The thread goes through the needle from front to back.

Bringing the Bobbin Thread Through to the Top

Once you’ve threaded the sewing machine, the last thing to do to set up your sewing machine is to bring the bobbin thread up through the little gap in the footplate underneath the needle.

This is the same whether you have a top loading or a front loading bobbin.

Holding onto the thread so that it doesn’t come out of the needle, turn the flywheel away from you gently. The needle will descend into the little gap. Keep turning the flywheel until the needle is back to its highest point.

The end of the bobbin thread should now be coming out of the little gap.

If it isn’t, try it again.

If this still doesn’t work, you’ll need to take the bobbin out, unwind a little bit more thread and pop it back in again. Then try again.

Now you’ve set up your sewing machine and it’s ready to use!

Set up your sewing machine and get ready to sew! The principle is the same whichever sewing machine you have, and steps will show you how,Sewing Machine